Sand production line overview

Sand production line is for a production of construction sand and stone production line equipment, energy-saving than traditional sand making about fifty to sixty percent . Due to sand production line equipment with reliable performance , reasonable design , convenient operation , high efficiency . Therefore , usually be used for a variety of rocks, gravel , river gravel made ??to meet the requirements of the various size of the sand used in construction , uniform particle size of sandy , high compression strength than natural sand , sand machine production of ordinary hammer sand more in line with the architectural requirements , can enhance the quality of construction .Sand production line is widely used in the stones factory , mining, metallurgy, building materials, road , railway , water conservancy , chemical and wait until the department . Production capacity to 50 - 500t / h, the particle size of the finished product can be combined and graded according to the different needs of users .

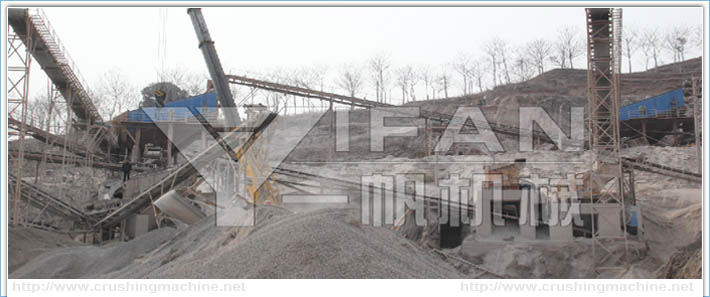

Sand production line(YF-33)

Sand production line works :

Material from the upper part of the machine vertical fall into the high-speed rotation of the impeller , high-speed centrifugal force , and another part of the umbrella form of triage in the material of the impeller around high-speed impact and crush the material after the impact each other again in the impeller and to the material between the chassis the formation of vortex repeatedly hit each other , friction and grinding , straight from the lower part of the discharge , the formation of the closed-loop recycled many times , finished granularity reach the required screening device control .

Sand production line crushing and screening in the design process , the joint equipment broken a device matching , and rigorous cross- space layout at all levels , so it has a small footprint , high economic efficiency of investment , the aggregates of good quality , powder the low output is characterized , at the same time equipped with advanced electronic control operating system , to ensure that the entire process a smooth feed and reliable operation , easy to operate , energy efficient .

Sand production line composed of equipment:

Sand making production line consists of vibrating feeder, jaw crusher , the third generation sand making machine ( Crusher ), sand washing machine, combination shaker and tape transfer machines and other equipment . According to the different technical requirements , the various types of equipment combinations, can produce a different particle size of sand and gravel .

Sand production line (YF-34 )

Sand production line workflow overview :

Artificial sand production line through the feeder , jaw crusher , respectively, into the (sand making machine , counterattack crusher ) through the vibration screening level required a variety of specifications stone , sand through efficient sand washing machine your demand for refined sand.

First , the stone consists of vibrating feeder evenly to the jaw crusher for coarse broken . Then the production cost of crude material transported by belt conveyor to the sand making machine for further crushing , crushing stone into the shaker sieve out the two kinds of stones , to meet the Sand feed size stones into the sand making sand , and the other part of the material back into the small break . Finished products into the sand making the gravel part of made ??of sand, to Jingxi sand cleaning (optional ) sand , and another part into the sand making machine is broken again .

Sand production line performance Introduction :

Sand production line high degree of automation , low running costs , crushing ratio , energy saving, large output , less pollution , easy maintenance , to produce the sand meets the national standards for construction sand , uniform particle size , grain shape is good , with the management level . Sand production line , sand equipment in the design process , due to broken equipment a reasonable match, as well as rigorous space at all levels across the layout, so it has a small footprint , high economic efficiency of investment , the quality of aggregates , powder production and other features for a low , and equipped with advanced electronic control operating system to ensure that the entire process the material smooth and reliable operation , easy to operate , energy efficient .

Sand production line features and performance advantages:

Investment is only 1/3-1/5 of the conventional production line in the same processing capacity .

Per ton of sand and gravel production cost is only 1/3-1/4 of the conventional production line .

A high degree of production automation , the following class production staff for three people .

More convenient to maintain operation mode, as opposed to the other production line equipment, equipment maintenance is simple , wearing parts using the latest high strength wear-resistant materials , loss of small , long life , can bring considerable economic benefits for our customers .

Fully automated operational processes , higher production efficiency , optimize work efficiency , high degree of automation , large crushing ratio , high efficiency , large handling capacity was cube -shaped , broken products , low flakiness content , without internal cracks , engage in the pressure high .

A wider range of application , successfully used in the processing of limestone, basalt , granite , cobblestone , broken rock , broken quality of the finished product fully meet GB14685-2001 standard , provides qualified for the higher road, rail , water , concrete mixing plant industries sand and gravel aggregate .

Sand production line (YF -35)

Sand production line use :

Sand production line equipment can be used for the aggregate of the hard limestone, granite , basalt , river gravel , smelting and refining multi- residue and other materials and artificial sands operations , applies to the application of water, building materials , highway , city construction and other industries .

[1]、Sand production line site under normal circumstances should be worthy of the closest to the quarry and materials Shi locations .

[2]、To implement the principle of land for conservation : the hillside enough to be built in the plains to meet the premise of F production , to make at least an area of , in particular, and little or do not account for the better .

[3]、Water supply conditions: to ensure water quality, water to meet the production needs and short-tailed bird live under the premise of the site to be as close to the water , attention must not spoon agricultural competition for water .

[4]、Have appropriate transportation conditions : road transport to facilitate convergence with the National Highway line , waterway transportation to facilitate the sharing of existing piers or selected the appropriate location of new terminals is required .

[5]、Production line site of the sand wash the engineering geological conditions : The site should avoid the construction of the fault , landslide and flood level should be to avoid the melting of Si , silt , humus , Furui bad lot or heritage conservation . Soil bearing general require no small 200kN/mz , and should not be set up factories in the current earthquake zone or more than two collapsible loess layer region .

[6]、As much as possible to save transportation costs , and conditions to strive to achieve the gravity or semi- gravity conveying the harm or pollution of the heart but also anti- rl waste x environment , rivers, Agriculture, Animal Husbandry and Fishery cattle production and hydrazine China area .

[7]、Breakthrough in sand making production line supply conditions: stone roughing problem , better to have Hr have to rely on power to shorten the transmission line , where the conditional use of the power grid power supply , subject to the provision of the amount of use to avoid self-built power plant increased investment and management costs .

Installation and maintenance of the sand making production line :

The the maintenance of and maintenance of the machine yes the the an extremely important recurrent source Xing the work of , It should work with the the closely cooperate with of the the correct operation and in a timely manner overhaul , and and so on , there should be full-time staff to carried out the on duty check the .

Sand production line equipment machine maintenance:

[1]、Note various parts of the machine is working properly .

[2]、The newly installed tire prone to loosening must always be checked .

[3]、Careful to check the wear parts wear , and pay attention to the replacement of worn parts .

[4]、The bearing temperature rise should be immediately stopped to check the reason to eliminate them .

[5]、The gears in operation if the impact of sound should be immediately stopped to check and eliminate .

[6]、Activities bearing can not put the base of the plane of the active device should be out dust and other objects in case the encounter can not be broken material on the bottom shelves move , resulting in a serious accident .

Sand production line equipment installation and commissioning :

[1]、Equipment, power configuration of the power cord and control switch .

[2]、Check is completed, the empty load test , test normal to the production .

[3]、The device should be installed on a level concrete foundation , is anchored .

[4]、Check whether the various parts of the loose bolts and host Kurakado , fastening , if to be tightened after installation .

Sand production line device configuration based on customer stone specifications and production and stone used to determine our customers for the sale, sale , sale of full-service production site based on customer configuration process , and strive to be the most reasonable the most economical production line .If you want to know more about sand production line equipment , such as how to install the production line to build sand ? Sand production line equipment cost? Sand production line set up some other performance can contact our 24 hours online customer service consultation or send us an e-mail to obtain pricing and service information .

- 上一篇:没有了

- 下一篇:stone production line--YIFAN MACHINERY